Opaque Sheet

- Length:

Any Transportable length from 1.2 Mtr to 11.8 Mtr or more

- Width:

Max. 1500mm Plain Width & 1100mm Profiled/Corrugated Width

- Thickness:

1.5mm to 4.0mm

- Light Transmission:

80 to 85 % Maximum

- Color:

Any Opaque Color

- Standards:

As per Indian Standard IS : 12866 or Any other International Standard on demand

FRP Sheets Range

“Rooffit” offers Opaque FRP Panels for Casing & Covering of Cooling Towers,\Water Treatment Plants, Roofing/Cladding in Industrial Sheds and are resistant to mild corrosive environments, like in coastal areas, acidic fumes, salt or acidic water, it allows exposure of the product in outdoor corrosive areas without alterations in their chemical composition and physical behavior.

These panels are lightweight, easy to install and long lasting and have a zero light transmission, it provides color durability, resistant to extremes of weather conditions, mild corrosive environment as well as creating an optimum aesthetic effect.

Normally, Color Coated Profile Metal Sheets are used for Roofing/Cladding in factories or industries under normal weathering and environmental conditions. In general, Mild Steel are highly corrosive material even under normal environmental conditions but the same is color coated with few microns of weather resistant paints which has limited self life.

But in presence of harsh weathering, chemical fumes or coastal environments, the M.S. Color Coated Profile Sheets are under constant threat of corrosion and not recommended for Roofing taking into consideration of minimum 10 years self life.

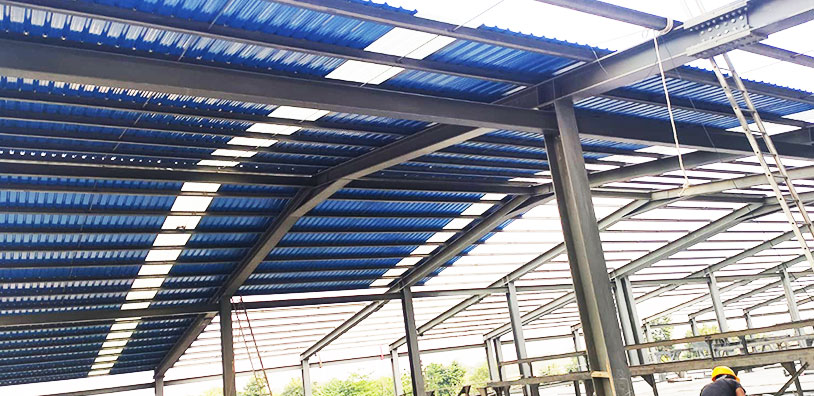

Covering & Casing of Cooling Towers

Covering & Casing of Cooling Towers Warehouses

Warehouses Industrial Sheds with mild Corrosive Fumes

Industrial Sheds with mild Corrosive Fumes Refrigerated Vans, Truck bodies & Bus Bodies

Refrigerated Vans, Truck bodies & Bus Bodies Marine Projects or Industrial Sheds near Coastal Areas

Marine Projects or Industrial Sheds near Coastal Areas Ceilings or Canopies

Ceilings or Canopies

Service Stations

Service Stations Water Treatment Plants

Water Treatment Plants

No Data Available

| S.No. | Parameters | Requirements |

|---|---|---|

| 1. | Tensile Strength | 80 Mpa |

| 2. | Impact Strength | 8 Joules |

| 3. | Shear Strength | 90 Mpa |

| 4. | Modulus of Elasticity | 5500 Mpa |

| 5. | Compressive Strength | 135 Mpa |

| 6. | Flexural Strength | 150 Mpa |

| 7. | Specific Gravity | 1.45 |

| 8. | Thermal Expansion | 3.0 X 10-5cm/0C |

| 9. | Thermal Conductivity | 158 watt/m 0C |

| 10. | Water Absorption | 2% in 24 hrs. / 26 0C |

| 11. | Range | -20 0C to + 130 0C |